Categories

New Blog

Tags

It can be said that bicycles have truly entered the carbon fiber era. Although I dare not say that they are high-quality and cheap, they are already much cheaper than ten years ago. However, this does not affect the selling price of those carbon fiber bicycles that are positioned as high-end. Among different bicycle brands, manufacturers always like to use some vague descriptions or high-end terms to introduce their carbon fiber materials and manufacturing processes. But if you can dig a little deeper, you'll find that these things they're talking about and promoting are actually very similar things. However, even so, the resulting frames are diverse.

In carbon fiber bicycle frames, more detailed design, testing, correct selection of materials, how to lay them, ensuring manufacturing consistency, etc., all make differences between different brands and models, including price.

So, how does carbon fiber become a frame step by step? What technologies and methods will be used in the manufacturing process? What are some issues that we keep misunderstanding? If everyone uses the same materials, why is one frame better than another?

Making carbon fibre

From raw materials to acrylonitrile

To begin making carbon fibre, manufacturers take ammonia and propane and put them together in a chemical reaction. Both of these are naturally occurring compounds: ammonia is found in your wee, among other things, and propane is found in fossil fuels and natural gas. The result when you combine these two things is a liquid called acrylonitrile, which is the building block of carbon fibre.

From acrylonitrile to polyacrylonitrile

The next step is to react the liquid with itself using a chemical reaction called free radical polymerisation. To do this, you add a very small amount of a catalyst called an initiator, which causes all the individual molecules of acrylonitrile to stick together in long chains.

Think of each molecule of acrylonitrile like a drunk person at a wedding party. The special chemical initiator is like that annoying drunk uncle that initiates a conga line. One by one, people join on, and the chain of people (molecules) gets longer and longer. These long chains of acrylonitrile are now a polymer called polyacrylonitrile – poly means many – and this is how 90% of the carbon fibre we know and love is made.

The alternative method: coal tar and pitch

Some of the other 10% is made in a process using coal tar and pitch. This is a more expensive production method that results in super stiff fibres with a really low thermal coefficient of expansion, meaning they don’t change size when exposed to different temperatures. This carbon isn’t really important for us, though. It’s used in spaceships, not bikes.

Sticking briefly with that conga analogy, additives can be added into the conga lines in order to tweak the material properties of those acrylonitrile strands. This is dependent on the final purpose of the carbon fibre that's being made: whether it's for bikes, trains, or whatever else. Of course, this is a gross oversimplification of a complex process, but hopefully you get the idea.

Cross-linking the fibres

The polyacrylonitrile (or teeny tiny conga lines, if that's easier) chains are then drawn out into fibres or strands and wound onto big bobbins. They're then spread out in an oven and heated in the presence of oxygen to about 200 or 300°C in order to oxidise them. This is a really important part of the process, as it builds cross-links between the strings of polyacrylonitrile.

Going back to my favourite conga analogy, what happens is you get multiple conga lines and get them to line up next to each other parallel you then get them to join hands, cross-linking those lines together, and this makes it really really strong. A carrier bag is made from carbon much like carbon fibre, but it's made from polyethylene which doesn't have that cross-linking going on. As a result, it's strong in one direction but will tear in another. By cross-linking the fibres, it increases the fibre density and makes carbon fibre really strong.

Carbonisation

The next part of the process is called carbonisation. Manufacturers take the strands of carbon fibre and heat them to 1,000°C or more without the presence of oxygen. The lack of oxygen stops the fibres from burning, and causes the carbon strands to vibrate. This vibration breaks chemical bonds to non-carbon atoms, which are then released, and it strengthens the bonds between carbon strands. Scientists don’t actually know why this happens, but they know it works. The heating process improves the crystalline structure of the carbon, essentially making strands of graphite.

High vs low modulus carbon

The interesting thing about carbonisation is it largely determines the modulus of the carbon fibre. The longer it’s cooked, and the higher the temperature, the more non-carbon atoms are expelled from the material. With that, the strands lose weight and volume, leaving you with a purer carbon fibre. The purer it is, the higher the modulus. Higher modulus carbon fibres are stiffer, but they're more expensive because they require more time in the oven and higher temperatures. So that's what bike companies are talking about when they talk about high and low modulus carbon fibre in their bike frames.

Adding resin

Having carbon fibres on their own isn't great. They're super strong and have high tensile strength, but they're also quite brittle. That’s where the resin comes in, or, as it’s technically named, the matrix (you don’t need to take the red pill to see it, though).

Carbon fibre is a composite material, which is a combination of two or more materials. By combining different things together, you can combine their physical properties and make a new super material. A great example of a composite material is reinforced concrete. You've got the steel wires surrounded by a matrix of concrete, making it much stronger than just steel wires on their own or standard concrete. Carbon fibre is much the same, just on a smaller scale. You've got the carbon fibre wires surrounded by resin, which together forms the matrix.

This process isn't very simple either. Firstly they need to rough up the surface of the carbon fibres, just like you’d rough up the surface of an inner tube before sticking on a patch. For carbon fibre, they usually do this by dragging the strands through baths of nitric acid. With the fibre surface roughed up, a special coating called sizing is applied. This protects the fibres so they can be handled and processed more easily further down the line.

Adding the resin

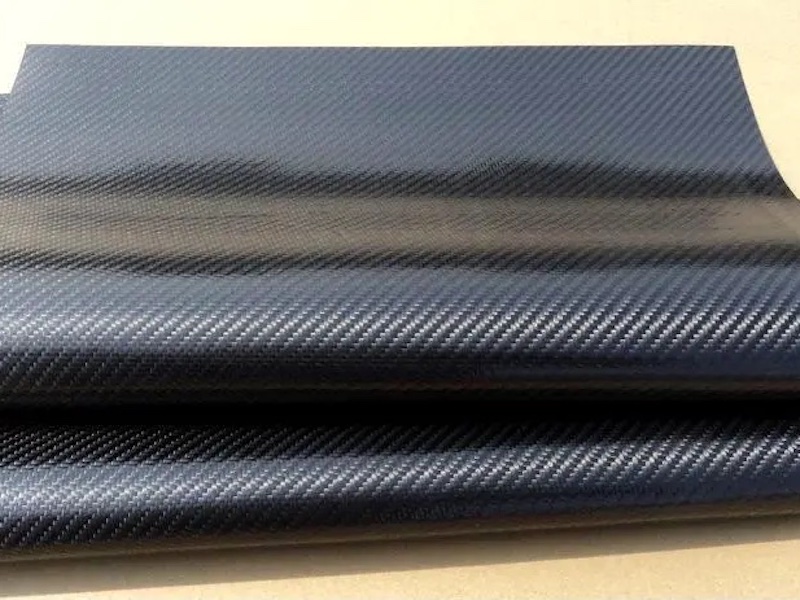

At this point, some carbon fibre is spooled onto big bobbins, but most is woven into sheets and sent to prepreggers, who apply a resin to the matrix. The resins they use are closely guarded secrets, and different resins are used depending on the intended use of the carbon fibre. For the bike industry, they mostly use epoxy resins. The prepreggers impregnate resin into the sheets of carbon, then roll it up and send it to bike manufacturers.

Once they get their hands on it, bike manufacturers cut it into the shapes they need to make bikes and begin layering and moulding their frames.

The alternative method: custom weaves

The carbon fibre that is sent off as a spool is used by specialist manufacturers like Time and Lightweight. They weave or filament wind carbon fibre in-house, so they take strands of carbon fibre with no resin in it and then they weave it into the shape they want. And as that weaving process happens, they also apply resin. Lightweight says this allows them to be more efficient with resin, which basically means they use less and achieve a lower weight. As you can imagine though, it’s more expensive.

Where it’s made

Given how widespread carbon fibre is, there are surprisingly few manufacturers worldwide. By far the biggest is a Japanese company based in Tokyo called Toray. There's also Hexel based in Stamford, Connecticut, Mitsubishi in Sacramento, California and SGL Carbon based in Wiesbaden, Germany, among others.

The future of carbon fibre

Material scientists are always looking for higher-performing resins, higher-performing fibres, and any incremental improvements to carbon fibre. In terms of big steps though, the most exciting idea is to form carbon fibres from carbon nanotubes. Think of these as sheets of graphite rolled into tubes. They’re much stronger than the pan-based fibres that we use at the moment. In fact, if you made your bike from them it’d be bulletproof. If you made a t-shirt out of these it'd be bulletproof. You could even, according to scientists, make a space elevator from them, they're that strong. The problem is that we haven't yet developed a large-scale cost-effective, scalable way of manufacturing them in high volume and in a large size that can actually be physically weaved or woven into objects.

Scientists are looking into ways to make carbon fibre manufacturing greener, too. Currently, there are a lot of nasty chemicals involved, like ammonia and propane. People are researching biological precursors that might work, such as lignin, which is a fibre found in plants like celery.

Finally, there’s a lot of work being done to find a way of recycling carbon fibre. Currently, it’s pretty much single use, although some companies are finding ways to use chopped up carbon fibre as 3D printer filament. It may be the current wonder material, but there’s still a lot of ways we could improve the manufacture and use of carbon fibre.