Categories

New Blog

Tags

Bicycle Wheelsets are fundamental to your cycling experience. A great wheelset can transform the performance of your bike and choosing whether to go with road clinchers, tubeless, or carbon road bike wheels is a major decision.This article will help us to know the wheelsets better!

Hubs: Hubs are the central component of the bike wheel structure. To put it simply, wheels rotate on hubs. The mechanism behind this is the wheel’s bearings and axle.

Bearings: Wheel bearings enable the hub to rotate on the wheel axle. Hubs either have cartridge bearings or cup and cone bearings. Cartridge bearings are now increasingly popular in hubs due to simple installation and require no maintenance. Cup and cone bearings are easy to service, but you must adjust very carefully to ensure adequate friction. For ultimate performance look out for ceramic bearings, these are the smoothest and roundest bearings available.

Spokes: Spokes provide support to the rim and distribute pressure evenly around the bike wheel structure. They are either round or aero/flat/bladed in profile. Aero/bladed/flat spokes are rapidly becoming a standard feature on wheels of all prices. They offer an aerodynamic advantage while retaining the strength of a standard round spoke. The spokes are kept in tension on virtually all but the most expensive wheels with small nuts, called nipples.

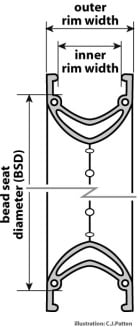

Rim: The wheel's rim sits on the outside of the wheel and has two main functions; to hold the tyre and provide a braking surface (for rim-brake bikes, not disc-equipped bikes). The rim width will affect the tyre width which could have a significant impact on rider comfort, and the material of braking surface will impact braking performance.

Nipples: Nipples add tension to the spokes and are often made from brass for strength. Aluminium can also be used to save weight, which helps with reducing rotating mass.

What makes a good wheel?

Choosing a good wheel will depend largely on its intended purpose, however whilst difficult to nail all aspects, ideally a good set of wheels will be durable, have dependable hubs, provide confidence inspiring braking, be stiff for power transfer, yet also be lightweight.

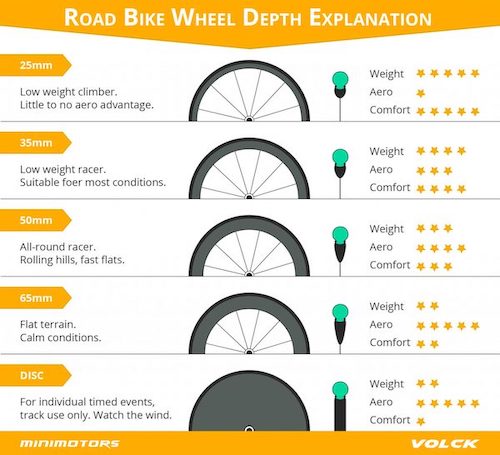

Lightweight wheels keep rotating weight down by having a shallow rim profile and low spoke count. As well as reducing overall weight, a fringe benefit of this is comfort. Deeper wheels are fast but the ride quality is often described as 'harsh', conversely lightweight wheels often provide good levels of compliance. Quality lightweight wheelsets will typically be below 1,400 grams, some extremely lightweight wheelsets coming in under 1,000grams for the pair!

Aerodynamic wheels aim to be as fast as possible by reducing drag. Aerodynamic wheels are typically greater than 40mm deep at the rim and are becoming wider as well. This speed does come at a cost with deep-section wheels more susceptible to crosswinds which can make them difficult to handle, and the extra material does add weight.

Wheelsets not so focused on performance commonly have features which make them more appropriate for everyday use or general training. The braking surface is aluminium providing better performance in all weather conditions when compared to carbon fibre, higher spoke counts are used to aid strength, and rim width is wider to cater for larger tyres. As a result of these features, weight increases with quality wheelsets typically ranging from 1,500 - 1,800 grams.

Most entry to intermediate level wheels will feature aluminium rims of varying quality, while high level wheels will typically feature rims made of carbon fibre which reduces the weight while increasing stiffness.

Aluminium as a rim material provides better braking performance than carbon fibre, which tends to perform poorly in the wet and on long descents as heat builds up under braking. Based on this, some brands offer an aluminium braking surfaces fitted to a carbon fibre rim. It’s worth noting however that these designs are typically heavier than a single-material rim.

Braking: Rim or disc

The shift to disc brakes has well and truly begun and is quickly becoming a new norm on road bikes. Moving away from rim and conventional caliper braking affords manufacturers some experimentation when it comes to both frame and wheel design as well as the obvious benefits of increased stopping power.

Wheelsets that use disc brakes don't need to have a brake track or confirm to a specific width in order to fit into tight fork and frame clearances. As a result, wheelsets for disc brake rims can have a modified profile to improve aerodynamics and performance. The drawback is that wheelsets for disc equipped bikes will have to be stronger to contend with the additional braking forces, meaning more spokes and specific hubs, which could potentially offset any weight saving or other performance gains. However, weight saved at the outside of the wheel (rim) has a far more noticeable impact on how light it rides than weight closer to the hub.

A huge benefit is the performance of carbon wheels, which traditionally have poor braking when compared to wheels with an aluminium brake track. Disc brakes allow for the performance benefits of carbon wheels to be maintained (or improved upon) without reducing the braking performance.

Wheels designed for use with disc brakes should not be confused with aerodynamic 'disc' wheels which form a single piece from hub to rim in the effort to reduce wind turbulence in time trial racing events.

A wheel's rim width and depth will largely dictate how it rides and feels.

The trend is for modern rims to be wider, resulting in better aerodynamics and improved comfort through greater tyre air volume. This coincides with the shift to larger tyres that are said to improve (lower) rolling resistance as well as comfort by running at a lower pressure.

The depth of the rim will affect the aerodynamics of the wheel and the handling of a bike. Generally the deeper the rim, the more aerodynamic, but also the harder to handle given they will be more affected by side wind than a shallow rim. The extra material required will also create a harsher ride, not offering as much compliance as a shallower wheel. It's worth noting that not all deep rims are created equally, and the exact profile varies greatly between brands. The best options manage to achieve fast speeds while being well controlled in cross winds.

Deep-section wheels will typically measure at least 40mm from the rim to the nipple, some extending to over 80mm.

The total number, shape and material of the spokes on a wheel will vary. High spoke counts (having a lot of spokes) increase the robustness and durability but come with a weight penalty. Spokes come in a variety of materials, including steel, aluminium, carbon fibre and titanium. Steel spokes are by far the most common.

The total number, shape and material of the spokes on a wheel will vary. High spoke counts (having a lot of spokes) increase the robustness and durability but come with a weight penalty. Spokes come in a variety of materials, including steel, aluminium, carbon fibre and titanium. Steel spokes are by far the most common.

The spoke count of front and rear wheels will vary, rear wheels having more spokes as more forces are applied (drive forces and additional weight load). Typically a lightweight front wheel will have between 18-24 spokes, while the rear wheel will have between 20-28 spokes. This is in stark contrast to the early days of wheel building when front wheels would have over 30 spokes, and rear wheels would have over 40. As materials and manufacturing processes have improved, spokes counts have gone down, reducing weight without compromising performance.

A flat spoke, often referred to as a 'bladed spoke', can provide some small aerodynamic gains over a rounded one. Although more expensive, bladed spokes also help to reduce weight without sacrificing strength.

Normal spokes are either 'straight pull' or 'J-bend'. 'Straight pull' spokes have no bend at the head and require specific hubs, 'J-bend' spokes are the more traditional option, featuring a 90 degree bend at the hub end which looks like a 'J'.

Benefits of the straight pull spokes are; more precise alignment, stiffer, more responsive wheel, and a decrease in weight. The drawback of straight pull spokes is that many companies make proprietary spokes and hubs which means sourcing a replacement spoke can be time consuming and potentially expensive. J-bend spokes are often easier to replace and perform close to straight pull spokes in terms of quality and strength.

Butting or 'butted' is a term you'll come across if looking at round spokes. Simply put, butting is the process of varying the thickness, and so a double butted spoke would offer two different diameters along its length. Butted spokes are typically stronger and more durable than 'straight gauge (one diameter) spokes as they help dissipate stress fatigue better.

The freehub is found on the rear wheel hub and performs two functions: to drive the rear wheel and allow it to coast. A fixed hub also drives the rear wheel but doesn't have the ability to coast, requiring you to pedal the whole time the bike is moving.

The freehub is found on the rear wheel hub and performs two functions: to drive the rear wheel and allow it to coast. A fixed hub also drives the rear wheel but doesn't have the ability to coast, requiring you to pedal the whole time the bike is moving.

Manufacturers have different freehubs so be sure to check your gears are compatible. Shimano and Campagnolo freehubs both use a spline system to connect the cassette to the freehub, but the diameter and spline-type differs, meaning they are not compatible. SRAM cassettes will work with Shimano freehubs, but not with Campagnolo.

The majority of new wheels being sold are 11-speed compatible which feature a wider freehub body to handle the wider spacing of 11-speed cassettes. With the simple use of a washer, these are backwards compatible with 8, 9 and 10-speed cassettes too. However, older 8, 9 or 10-speed hubs cannot fit an 11-speed cassette (except Campagnolo wheels/cassettes).

As cost of the wheelset goes up so does the quality of components used. In the case of bearings inside the hub, they typically go from steel to ceramic. A good ceramic bearing is rounder, smoother and harder than an equivalent steel bearing, therefore reducing friction and improving performance as a result. However, a good steel bearing will typically outlast and outperform a cheap ceramic bearing.

As cost of the wheelset goes up so does the quality of components used. In the case of bearings inside the hub, they typically go from steel to ceramic. A good ceramic bearing is rounder, smoother and harder than an equivalent steel bearing, therefore reducing friction and improving performance as a result. However, a good steel bearing will typically outlast and outperform a cheap ceramic bearing.

As well as the material of the bearings, proper lubrication will influence how they roll and the amount of friction that is produced. Friction in the bearings reduces performance and slows the wheels down. Excessive friction occurs if the bearings aren't appropriately lubricated, if debris or other substances get into the bearings, or if the bearings are flushed of their lubricant by high pressure washes. Here, higher quality hubs offer improved sealing from the elements, which keeps them rolling smoother, for longer.

The lower the viscosity of the lubricant, the less friction, but durability may be compromised as a result.

Bearings are either cartridge (sealed) or loose ball (cup and cone). The cartridge or sealed system features an inner and outer race, with the bearings sitting in between them, all enclosed within a single unit. The cartridge bearing is then pressed into the hub shell with the axle going through the middle. A sealed bearing is a single unit, if it wears out, replacement of the whole bearing cartridge is required, but fairly cheap to do so.

Loose ball or cup and cone bearings are most commonly found on Shimano products and entry-level wheels. Cup and cone bearings have multiple pieces and loose bearings. They are not enclosed like cartridge bearings, instead loose ball bearings are sandwiched between a fixed outer race (usually part of the hub shell), with an adjustable cone shaped inner race threaded onto the axle. If the bearings are worn too far, they can wear the hub surfaces causing enough damage to require complete replacement of the hub. On the positive side, they're easy to maintain to prevent this from happening. To service such a hub, you’ll need a couple of special thin spanners known as ‘cone wrenches’.

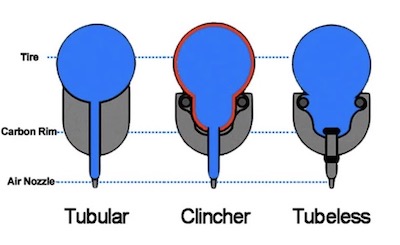

It's worth knowing the three different tyre types that fit onto a wheel as they require a specific rim. Tyres will either be 'clincher', 'tubular' or 'tubeless' and the wheel will specify which tyre it is compatible with. The majority of road bikes available for sale will feature clincher tyres which need an inner tube to hold air.

Clincher

The most common form of tyre currently used on road bikes. Unless stated, it's a fair assumption that any new bike bought will feature clincher tyres. Clincher tyres require a tube to inflate and hold air, while the tyre will feature either a steel or kevlar fiber bead on it's edge to hold it in the rim.

Tubular

Tubulars also use an inner tube but in a very different way. The inner tube of a tubular tyre is sewn directly to the tyre, which is then glued or stuck directly onto the rim. Professional racers almost exclusively use tubular tyres thanks to their reduced weight, enhanced rolling resistance and road feel. In case of a flat tyre, disc brake tubulars rims can also be ridden on with relatively little risk of the tyre rolling from the rim.

The drawback to tubular tyres is the extensive work it takes to first apply the tyre to the rim and the laborious task of replacing the tyre should you get a flat. Add in the price of such tyres and it’s certainly an item best kept for the dedicated racer.

Tubeless

Tubeless tyres have long been used in mountain biking and are slowly making their way into the road bike world. Trek has equipped ‘tubeless ready’ rims on the majority of its road bikes since 2015 and Giant exclusively features tubeless tyres on high-end models as of 2017.

As the name suggests, tubeless tyres require no inner tube, and instead attach to a specific rim design that creates an airtight seal. It's a technology very similar to that found in modern cars and motorbikes.

Tubeless tyres are considered superior to clincher tyres because they create less friction which improves rolling resistance, can be run at a lower pressure improving comfort, and are said to offer better puncture protection. To prevent punctures, tubeless tyres can be used with liquid sealant which can be inserted into the tyre to help immediately seal small punctures if they occur.

Xiamen Tour de Cycling Industry&Trade Co.,Ltd. is a company specialized in all kids of carbon rims with disc brake or rim brake, we have more than 15 years experience ,more carbon frames, carbon bicycle rims,carbon bicycle forks etc can visit our website: www.xmtourdecycling.com